News

More Share, More Profit

[Tainan News ] Mold Power Co. has developed the [MP] brand and promoted a variation of hot runner systems and temperature controller systems. After 2006, a second plant was added to production. Mold Power invested another 30 million NTD into building the new plant and the equipment needed, in order to meet demand and to enhance capacity. And now it is in the process of covering orders from agents overseas and working to reinforce competitiveness with the new plant.

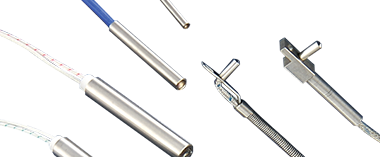

Mr. Chen, Zhong-Le, the general manager of Mold Power, says that Mold Power has already been committed to hot runner related business for nearly 20 years. In order to reduce plastic consumption and improve product quality, we have been actively involved in research and development, and expanding our plants to increase production capacity. We have promoted a series of products such as pin point gate hot runner systems, hot runner melt-rotate regulator technology, and MPT type hot runner temperature controllers. Furthermore, we have introduced a hot runner polishing machine to improve product quality and technology, and we have also solidified our foundation in the domestic hot runner market.

As the company explains, Mold Power has introduced CNC 4 axis engraving machine so that electronic spindles can be wrapped accurately on the copper sleeve and body to reach the thermal homogeneity required in the molding process of engineering plastics. And we have incorporated molding flow analysis with hot runner melt-rotate regulators to solve the problem of temperature variation between the inner and outer layer of the multi-cav mold to achieve a successful outcome in the actual operation of the light guiding plate. Hot runner melt-rotate regulator technology allows materials to reach multi-cavity molds (for hot runner and hot half system filling) and to balance the temperature inside and out.

The "MPT type hot runner temperature controller" is programed with a security circuit system. When the channels are connected falsely to 220V and 380V electric voltages, electro thermal and thermocouples can effectively protect the electro thermal and thermocouples from damage. The simultaneous multi-zone temperature control within a single panel can be programed up to four zones. The hot runner polishing machine polishes the hot runner inside the mold as smooth as a mirror to reduce the flow resistance of molten plastic, and the friction and shear forces that increase the color change speed. As a result, material consumption and costs are reduced and this technology can be applied to optical accessories, cosmetics and 3C industries.

In addition to the domestic market, Mr. Chen, Zhong-Le told us that there will be a move to expand to the foreign market within the year, including actively participating in the plastic and rubber exhibitions in India, Thailand, Vietnam, Malaysia and Indonesia. Moreover, MP will keep leading in R & D and innovation and anticipates expanding the “MP” brand through agents abroad and related services. Make the “MP” brand based in Taiwan and spread out through the international market. (Wu Qingqing)